QUALITY

Atkinson Engineering have a range of finishing processes in order to deliver high quality finishes to your parts, components and products. As an ISO 9001 : 2015 registered company, which provides the processes and management framework that ensures our products and services meet your requirements at all times.

ASSEMBLY

Thanks to the flexibility of our work force, we can assemble for you complete modules of products, building them to your specification and delivering them directly to you. We can also offer stock holding and call off arrangements.

STOCKHOLDING & DELIVERY

We offer a stockholding facility whereby components can be called off throughout the year and despatched for a next day delivery.

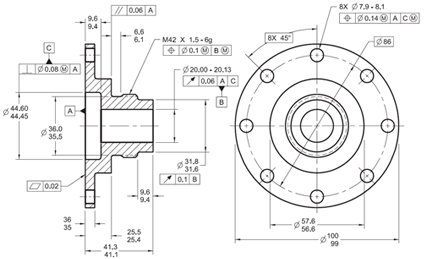

CADCAM

Our experienced engineers can use our CadCam system to configure programmes to produce your components on our CNC machines, this allows us to write code to produce 3D profiles, ellipses and detailed complicated parts with ease straight from our customers drawings.

VIBRATORY FINISHING

TURBEX PARTS CLEANER

AXIOM CMM X-600

Shop Floor Inspection System - Fast, accurate and reliable, the Axiom too CNC CMM comes in four different sizes with Y axis travel up to 1200mm. The Axiom too range of shop floor CMMs can be used with touch trigger probe, continuous contact scanning probe or with Aberlink’s revolutionary non-contact camera system.

ALLIGATOR AUTO BAND SAW

250mm vice feed fully automatic CNC bandsaw with mitre swing and ball screw feed The bandsaw is hydraulically controlled via inbuilt motors, giving quick and trouble free operation. The solid cast iron bow is controlled by a highly sensitive hydraulic down feed system operated at the main 7” touch screen control panel.

LUBRISPIN EC500 - MANUAL SWARF CENTRIFUGE

Our LUBRISPIN EC range of Manual swarf spinners are constructed for long lasting continuous operating. The machine housings are of a robust design with high quality steel. The Centrifuge is powered directly by a central positioned heavy-duty motor. The units have an interlocked cover to to prevent opening the lid during processing, timers for adjusting the cycles, emergency stop switch, signal lamp lights, and removable 3mm perforated baskets.